Have a question about solder paste evaluation?

Simplifying Prototypes, Mastering Production.

Your Solution to Scalable Production.

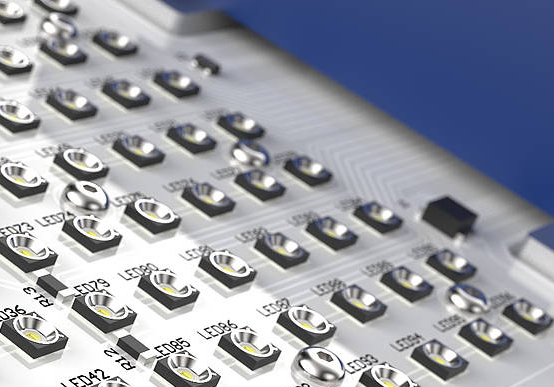

LED Solder Assembly

We take a solution-driven approach to all of our products.

With the ability to print at up to 150mm/sec, our no-clean, lead-free solder pastes have become the gold standard for LED applications. For our LED solder materials, we asked:

What if we could eliminate (or dramatically reduce) the chances of thermal voiding for our customers’ products?

About FCT Solder

FCT Solder provides the highest performing soldering products in the market. We offer many advantages through our solution driven solder products. Explore the various solder products that we offer including solder paste, bar, wire, and fluxes.

FCT’s solder paste and gel flux line includes: no clean, water soluble, RMA, pin probable, halogen free, and ultra-low voiding products.

FCT’s bar solder line includes SN100C, SN100Ce, SN100CL, and SN100Cle alloys.

FCT’s wire solder line includes SN100C and SAC305 alloys which are available with WS101 water soluble flux core and NC601 no clean flux core.

FCT’s liquid flux line includes: no clean, water soluble, rosin containing and rosin-free, low solids, and low or high activity levels.

Our products are formulated to work with many solder alloys including: Sn63/Pb37, Sn62/Pb36/Ag2, Hi Temp >88% Pb alloys, SAC305, SN100C, SN100CV, LF-C2, and other Pb-free options.

Engineering Support

Having issues with solder or your manufacturing process? Need help solving a solder problem? Talk to one of our engineers and let us help you solve your problem.

What Customers Say: