Low Temperature Solder

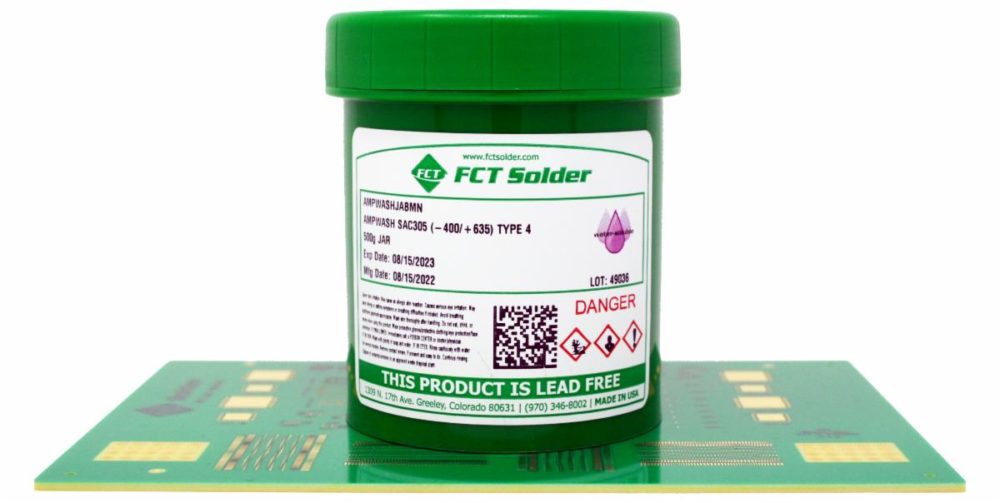

When you need low peak reflow temperatures, FCT Solder has you covered with TempSave B37.

Low temperature solders (LTS) protect thermally sensitive assemblies, mitigate warpage defects, and reduce energy costs. Try Low Temp and see for yourself!

Low temperature solders are designed to melt and reflow at lower temperatures than more traditional solder pastes. They are often alloys that incorporate tin (Sn), bismuth (Bi), or Indium (In), and typically have a melting point below 180°C. The exact characteristics of the solder will vary based on the manufacturer, the composition, and if additives are included to further modify the alloy. If you have questions about low temperature solders, or our offerings, use the button below to get in touch with one of our service reps today!

Advantages of Low Temperature Solder:

Reduced risk of thermal stress to heat-sensitive components.

Minimizes the risk of board warpage.

Reduced risk of Head-on-pillow and Non-wet-open defects.

Lower energy consumption and associated costs.

TempSave B37 Low Temperature Alloy

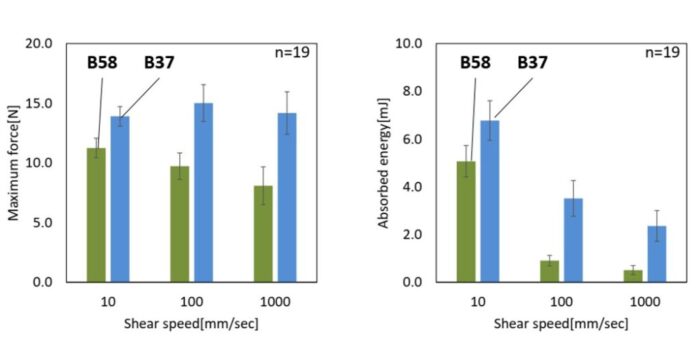

TempSave B37 is a low temperature alloy developed with reliability in mind. TempSave offers a significantly lower reflow temperature compared to traditional lead-free solders, while utilizing additive elements that enhance the alloy structure and solder joint interfaces to reduce brittleness normally attributed to high bismuth alloys. Additionally TempSave can improve drop shock and impact shear compared to the industry standard Bi58 eutectic.