LED Solder Assembly

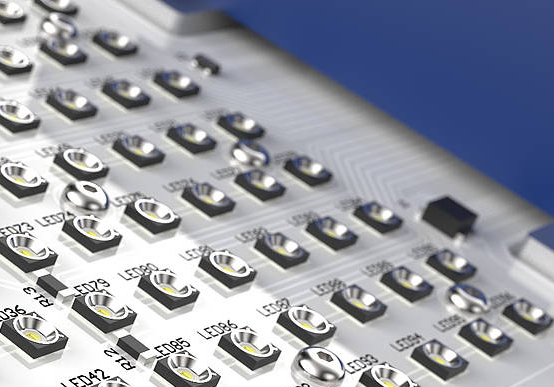

Our LED solder assembly materials are designed for manufacturers who need a reliable, high-quality product that minimizes voiding and maximizes diode output.

As LEDs have become more and more popular, we’ve kept pace with products specifically created to solve the problems faced by manufacturers.

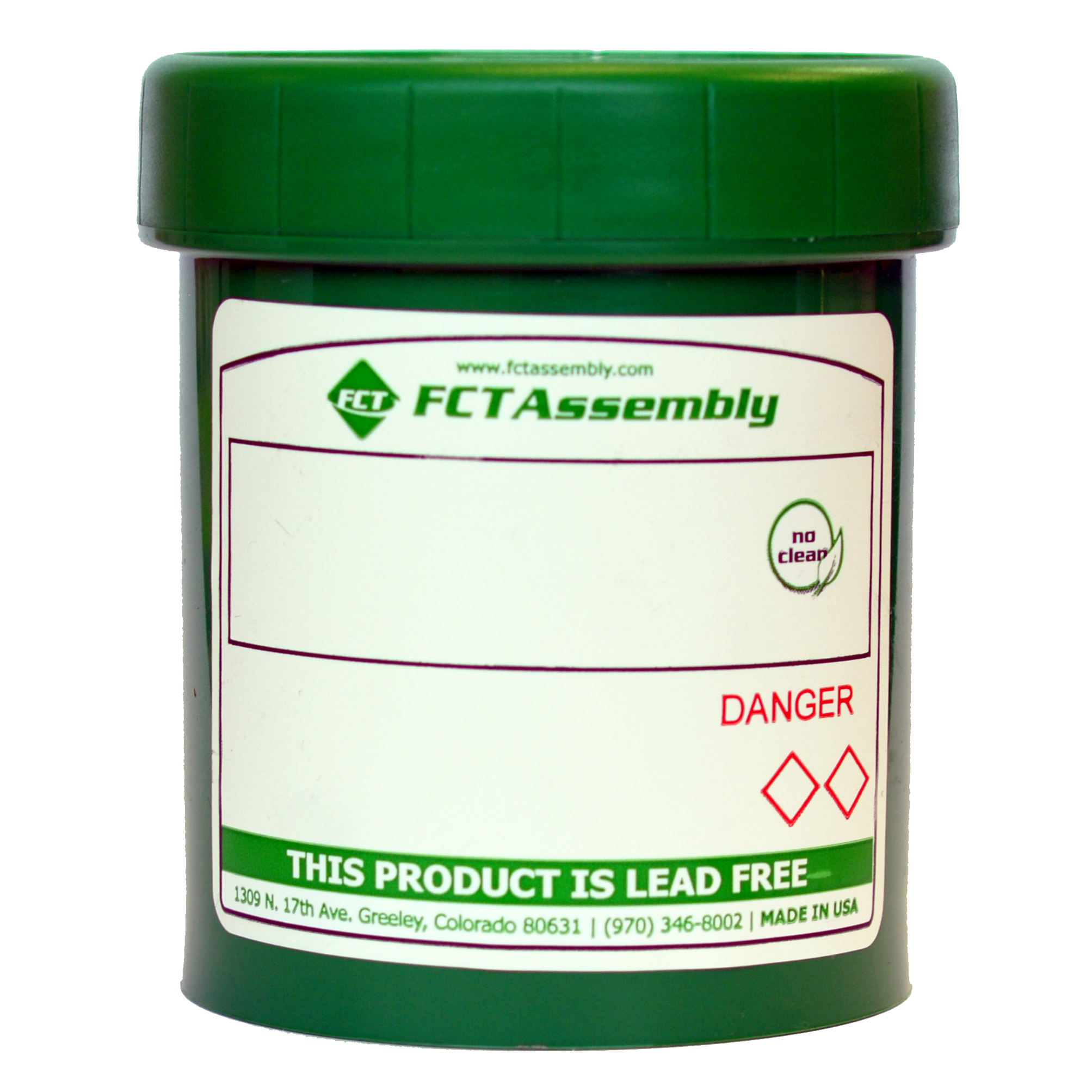

FCT Solder’s LED soldering materials are designed with high-speed productivity in mind, to allow manufacturers maximized throughput. With the ability to print at up to 150mm/sec, our no-clean, lead-free solder pastes have become the gold standard for LED applications.

Our no-clean, lead-free solder pastes are popular for LED applications because our no-clean fluxes eliminate the need to wash away flux residues. Clear, colorless flux residues help maintain the brightness and reflectivity of the LED. In addition, shorter reflow profiles and high-speed printing increase manufacturing throughput.

Benefits of our LED solder

Read on for more insight on how our solder pastes can unlock a more efficient process and longer-lasting LEDs.

Solution-Driven Solder Assembly Materials for LEDs

LED (light emitting diode) technology has effectively replaced incandescent lighting in many applications. From automotive to in-home lighting to consumer electronics, LEDs have surged in popularity because they are relatively inexpensive to manufacture and make sense for many applications.

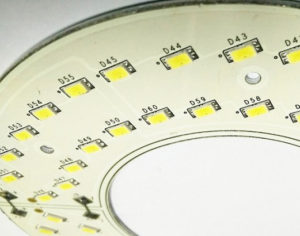

Although LEDs are prized for being more durable and longer-lasting than traditional incandescent bulbs, one of the biggest challenges manufacturers face when working with LEDs is heat. Overheating is one of the most common reasons LEDs fail. When heat can’t escape via the thermal pad, it dramatically shortens their lifespan.

FCT takes a solution-driven approach to all of our products. For our LED solder materials, we asked: what if we could eliminate (or dramatically reduce) the chances of thermal voiding for our customers’ products?

Designed to Keep Components Cool for a Longer Life

Solder-paste induced voiding can prevent heat from escaping and cause delicate components to overheat and dramatically shortening the life of the LED.

Solder-paste induced voiding can prevent heat from escaping and cause delicate components to overheat and dramatically shortening the life of the LED.

Our advanced flux formulations are the foundation for solder materials that are designed to lengthen the life of your LED products. By reducing the chances of voiding, our solder pastes help ensure that any heat produced can escape and components remain cool.

The bottom line: LEDs won’t overheat, which results in longer lasting products.

Print Quickly for Better Productivity

Our pastes are designed for high-speed printing. Use them to gain efficiency, increase your throughput, save time and money.

Solder Materials You Can Rely On

When you order your solder materials from FCT solder, you’re getting:

- Fresh paste. All our paste products ship within four working days to ensure maximum freshness.

- Zero-halogen and zero-halide products. Our products deliver good activity and stability.

Solder Products for LED Assembly

NL932HF

NL932HF is a zero-halide and zero-halogen, lead-free solder paste that allows for repeatability and consistency. It allows for high-speed printing to boost your LED output and efficiency. The no-clean paste cuts down on the time and expense of washing and is great for LED applications.

Flux Type: No Clean for bright and reflective LEDs

Alloys: Lead-Free

Classification: ROL0

Halogen: Zero

AMP OnePT

Voiding is a huge issue for LED projects due to the heat and thermal cycling required. AMP OnePT solder paste from FCT Solder is redefining the voiding standard for PCB assembly to help you deliver unparalleled quality. Take LED projects to the next level by boosting your yield and extending the life of your products.

By combining industry-low levels of voiding performance with excellent activity and decreasing the potential for solder balling and graping, AMP OnePT delivers LED assemblers an unmatched ability to amplify their process window while ultimately achieving higher yields.

AMP OnePT Properties

- Minimizes voiding that can kill LEDs

- Low solder balling

- Halide- and halogen-free

- Excellent wetting

- High activity

- Long stencil life

- Great choice to maximize yield and reliability of LED projects