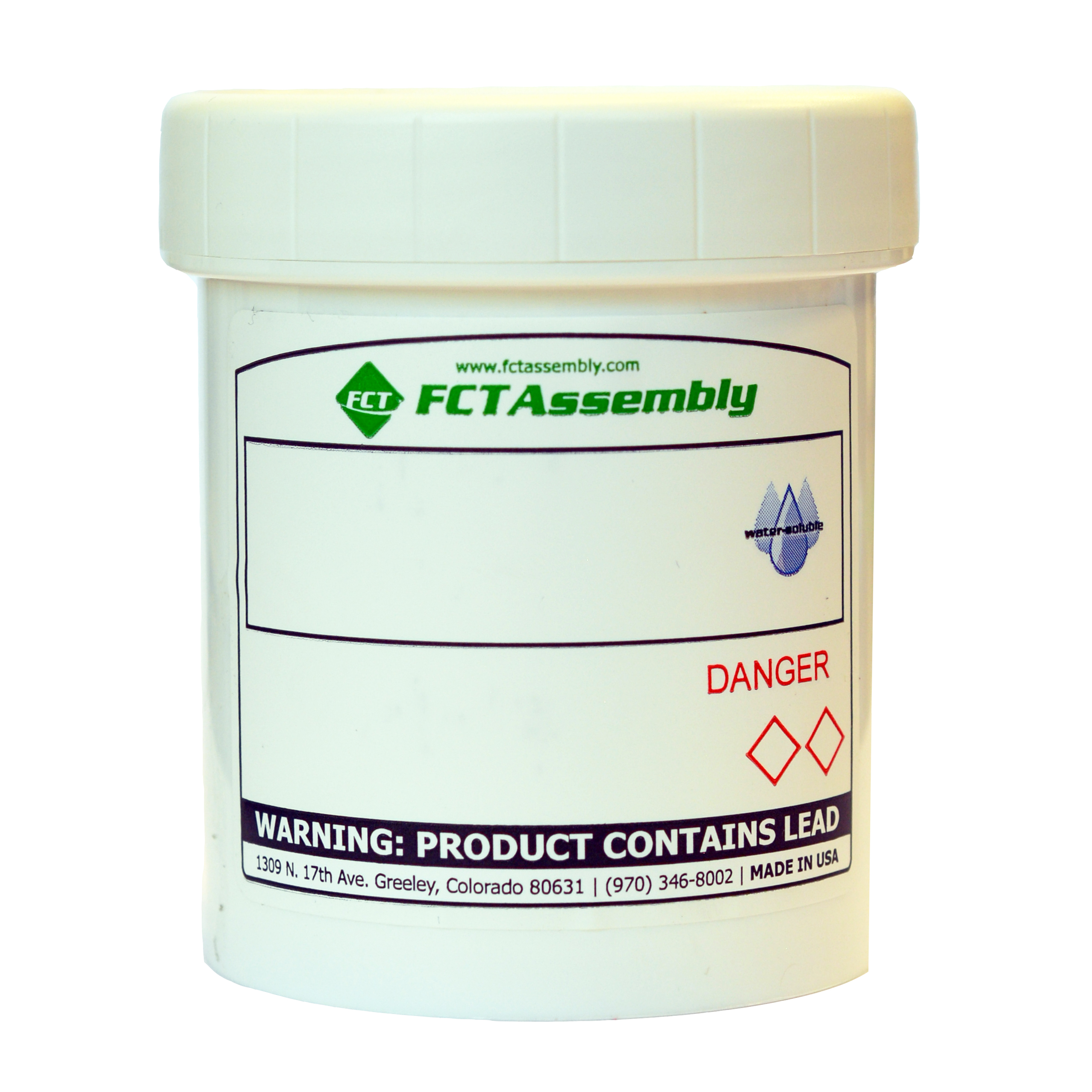

Solder Materials for Military Applications

We understand that military production requires high-reliability products that are reliable over time and in critical environments. Our solder materials for military applications are dependable, long-lasting, and durable.

High-reliability leaded and lead-free options

Finding top-notch tin lead products can be a challenge as other industries transition away from lead. We’re dedicated to maintaining these product lines to deliver the highest levels of reliability.

Why FCT Solder for military applications?

Military electronics manufacturing has no room for failure. Our solution-driven products are developed based on our own research and created to solve problems posed by other solder products on the market.

Many of our products are formulated specifically with antitombstoning, low slump, low graping, and low voiding characteristics.

We’re intimately familiar with the problems created by voiding, tombstoning, and other SMT defect issues — and we’re well versed in how to avoid them, as well as the tradeoffs that come with various methods and materials.

Contact us, and we’d be happy to help you choose the right product for your specific application.

Materials You Can Rely On

When you order from FCT Solder, you know you’re getting:

- Fresh paste, shipped within four working days to ensure maximum freshness.

- Low-graping products in both water-soluble and no-clean options.

- Zero-halogen and zero-halide products that deliver good activity and stability.

Process Solutions for Military Applications

Solder Balls

These are often formed during reflow and wave soldering due to poor wetting and other issues.

Recommended Products to Reduce Solder Balls:

Solder balls in a solder paste application are solved by using higher activity solder pastes. In the tin/lead world, this means RMA250 over NC676 although both have very low solder balling potential.

RMA250

RMA250 is a high activity, no clean solder paste that is classified ROL1. This high activity, along with its rosin-based chemistry, allows for improved cosmetics and excellent wetting on all surface finishes.

NC676

NC676 is a no clean, leaded solder paste that possesses a creamy, smooth texture. It is both zero-halogen and zero-halide. This product is classified ROL0 and is a rosin-based chemistry.

Tombstoning

Components lift up during reflow, which causes an open pad at one end. Tombstoning is particularly troublesome on circuit boards with a ground plane attached to one end of a small component, which creates a temperature difference from end to end of the component during reflow.

Our anti-tombstoning solder pastes are made with a mixture of alloys to create a melting range. This equalizes the force generated by reflow and coalescence of the solder powder at both ends of a component.

Recommended Products to Reduce Tombstoning:

Tombstoning can be solved through the use of our Anti-tombstoning solder pastes. Modification of the reflow profile can also help.

Voiding

Voids in solder joints can create mechanical weaknesses that lead to cracks in the solder joint. Voids can also interfere with heat transfer away from a component, which leads to thermal failure.

Recommended Products to Reduce Voiding:

In terms of voiding, our tin-lead solder pastes listed below have much lower void potential than most lead-free solder pastes.

WS159

NC676

RMA250

Alloys: Lead

Classification: ROL1

Halogen: Yes