Lead Free Solder

The usage of lead free solder in electronics accelerated with the implementation of the European Union’s Directive 2002/95/EC on the Restriction of Hazardous Substances (RoHS). These laws took effect on July 1, 2006. The restricted substances included in RoHS are shown below.

The intention of RoHS is to reduce the amount of these substances introduced to the environment. This forced many electronics manufacturers to use solders that are free of lead, mercury, and cadmium. Most lead free solders are based on tin (Sn) and contain a trace amount of lead (Pb) that is below the RoHS limit (1000 ppm = 0.1 % wt). Mercury and cadmium are not normally found in pure tin metal.

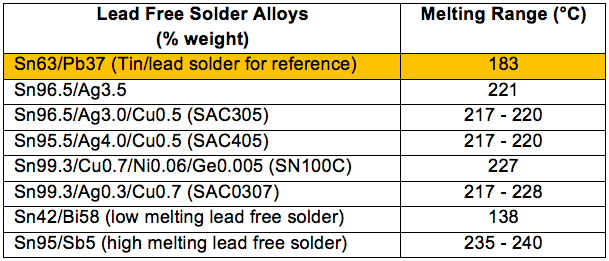

The process of using lead free solders requires higher temperatures than lead bearing solders. This is due to the higher melting points of most tin based lead free solders, which are shown below.

In most cases the melting point of lead free solders is 35 to 40 °C higher than Sn63/Pb37 solder. Lead free solders require higher temperatures in wave, selective, hand, and reflow soldering. The fluxes, circuit boards, and components used must be able to handle this additional heat.

Since the implementation of RoHS, soldering fluxes have been developed to give excellent performance with lead free solders. FCT Assembly manufactures and sells a wide variety of lead free soldering products. These include wire solder, bar solder, liquid flux, gel flux, and solder pastes. Please contact us for more details.